You are viewing: Home Air Pollution Control

Air is one of the four basic elements – Air, Water, Earth & Fire as per many ancient philosophies. Air is the earth’s environment. As far as human beings are concerned, air is all pervasive and the very pre-requisite of life. Sadly though, air is also considered the most “taken-for-granted” element and is generally polluted indiscriminately.

Air is a mix of gases in certain proportions which enables all living beings to breathe and survive. Pollution of air is introduction of substances in air that alter its constitution and have adverse effects on living beings. These substances can be particles, liquid droplets or gases and can be natural or man-made.

Introduction of various substances into air through vehicle exhausts, industrial production processes, or combustion etc are various man-made sources of Air Pollution. These are primary sources and if not controlled or polluted air is not treated before release in atmosphere, they may also lead to secondary air pollution. On global scale, Air Pollution is causing our atmosphere to warm up leading to various complications including climate change. On local level, it is silently, but very consistently, affecting our health and that of our future generations.

Air Pollution Control is thus of primary importance. At eros, we provide effective systems to deal with air pollution at its source. This enables our clients to not only maintain good working environments, but also meet all norms in this relation by concerned authorities.

We are one of the leading suppliers of Air Pollution Control Systems in India. We provide complete services from concept to supply to commissioning. Backed by in-house research, design and manufacturing facilities, we are able to customise our solutions to meet client requirements and expectations to the fullest.

Induction Melting Furnace is major steel producing technology using scrap & sponge iron (Directly Reduced Iron) as main raw material. This technology contributes significant steel making capacity in secondary steel sector in India.

Induction Furnace Process includes melting of various types of steel scrap in a pot. The energy required for the melting process is provided by electrical induction. The feeding of raw material in the induction furnace is on intermittent basis. As one charge of scrap melts, slag is removed from the molten metal and certain alloys are added to achieve the desired grade of steel. Molten metal is then poured into refractory lined buckets from where it is further poured in different sizes moulds to get the desired size of steel cast . Ingot/Billet is allowed to cool down and then the product is separated from the moulds.

Flue gases are generated during melting of scrap. The characteristics and volume of these gases mainly depends upon type of scrap used in the furnace, i.e. with the degree of contamination in the Scrap. These flue gases need proper treatment for removal of dust particles/gases before being discharged into the atmosphere.

Steel scrap comes from various sources and generally has contaminants/coating etc on it. When this scrap is heated contamination/coating etc disintegrates from steel and comes out either as slag or becomes air borne, thus causing air pollution. The major source of Air Pollution is:

The volumetric capacity of Air Pollution cannot be judged as such, but fair engineering estimation can be made with input data like:

The Control Practice adopted in controlling air pollution in this industry mainly depends upon following parameters:

The Following technologies are usually adopted for Air Pollution Control System in Induction Furnace industry:

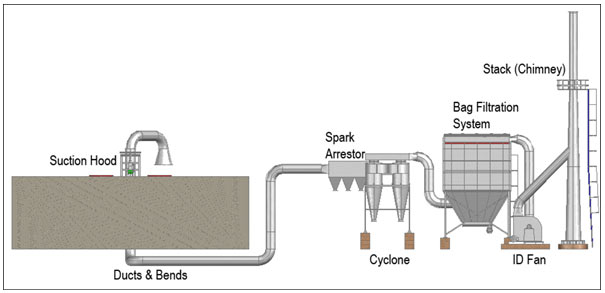

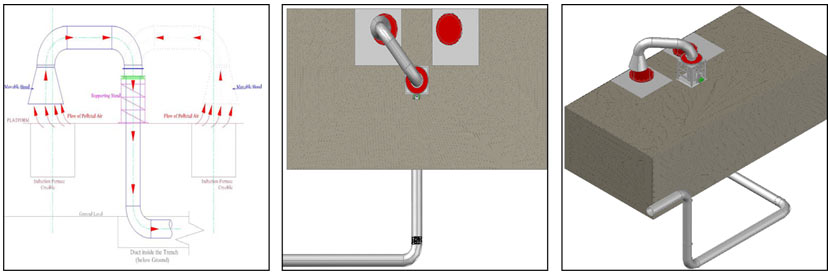

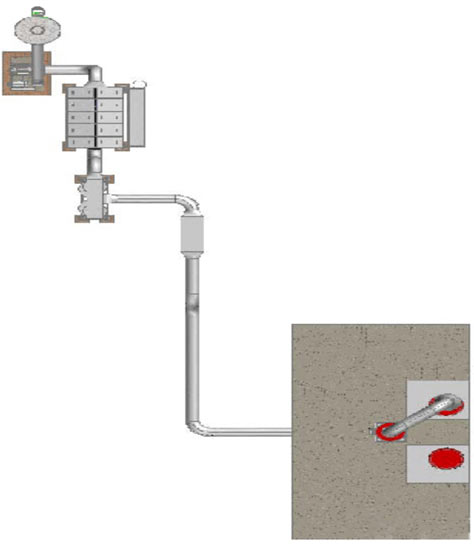

The furnace is fitted with Movable Suction Hood of capacities adequate enough for efficient suction of the total volume of flue gases generated from the furnace. The hood is provided with geared motor arrangement so that it can be brought near or away to furnace by reversible switch as and when desired during melting and feeding operation of the furnace. The size of hood depend upon the crucible dia, furnace capacity and suction volume of I.D. Fan. The main features of the hood are

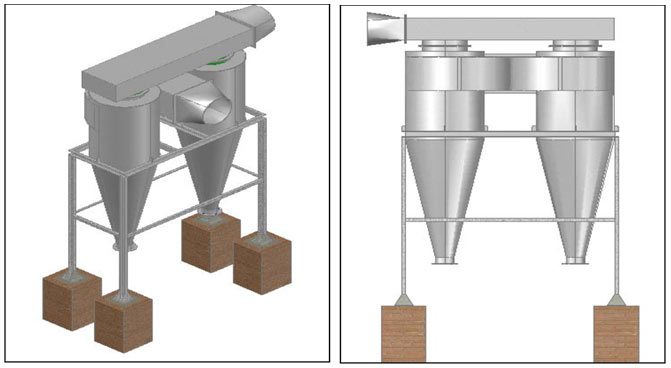

It is provided to capture the live particles (if any) from the furnace, to avoid the burning of the bags in the bag house. The mechanism of spark arrestor is based on impingement type so that particles strike the baffle plate at higher velocity at impingement plate and in the process large particles are arrested in the spark arrestor.

It is provided to capture the medium size live particles from the furnace, to avoid the burning of the bags in the bag house. The mechanism of spark arrestor is based centrifugal forces entering in a tangential inlet cyclone. The medium size particles are arrested in the cyclone so that bag house can be protected from bags burning.

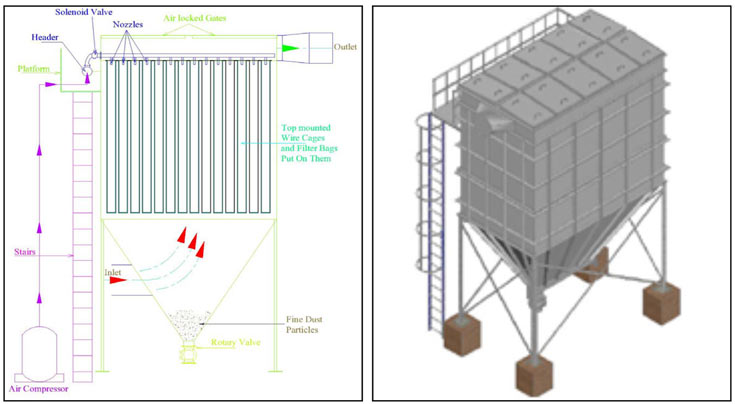

Unit has been provided with Bag House. The gases are fed to bag house. The Bag House removes fine particles and gases are fed to chimney through Blower. The collected dust on bag filter surface is removed with the pulse jet mechanism. The removed dust is collected in the hopper from it is conveyed through screw conveyor and discharged through rotary air lock valve.

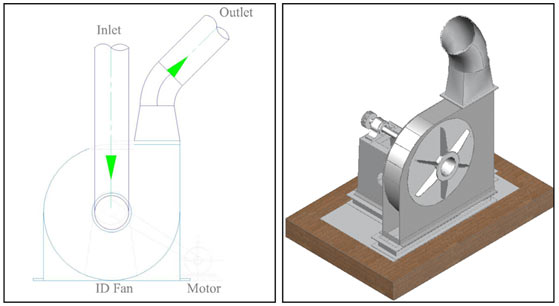

They have been provided for creating an adequate negative pressure in the system for efficient suction of gases.

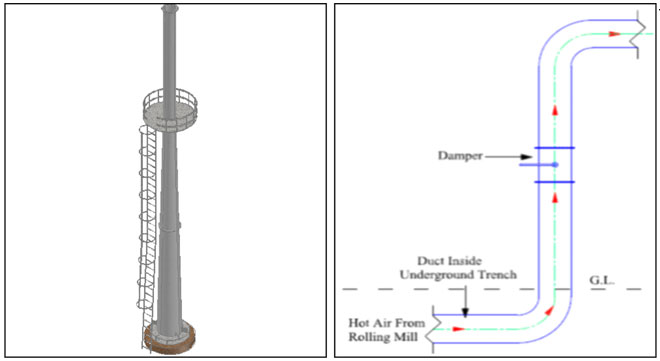

It is provided to release the treated gases into the atmosphere through an adequate height of the chimney. The air stack is provided with aerodynamic bottom part to enable easy flue gas entry and for structural strength.

Ducting and Bends are provided in the system for conveyance of gases at appropriate velocities and also to reduce the temperature by natural convection. An adequate length and size of ducting is necessary for proper conveyance of the gases at minimum pressure drop. The bends provided should be aerodynamic in shape so that there will be minimum pressure drop and no dust build up during operation. The main feature are:

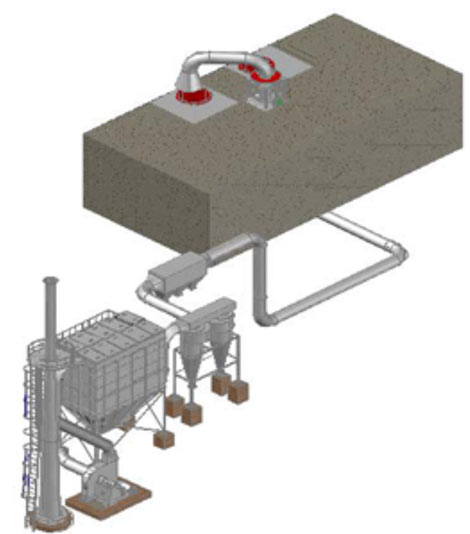

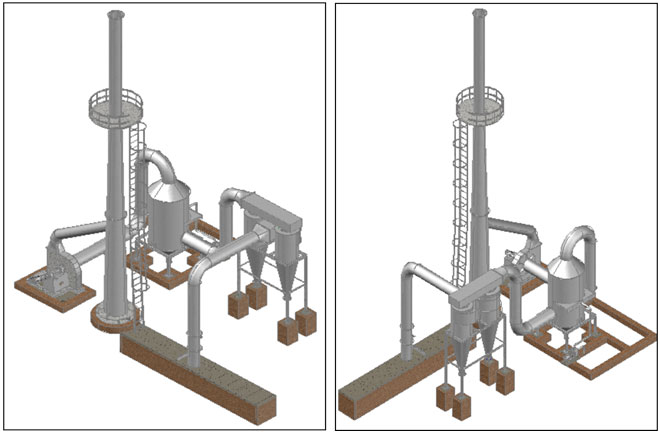

Isometric View of Air Pollution Control System.

Induction Melting Furnace is major steel producing technology using scrap & sponge iron (Directly Reduced Iron) as main raw material. This technology contributes significant steel making capacity in secondary steel sector in India..

Induction Furnace Process includes melting of various types of steel scrap in a pot. The energy required for the melting process is provided by electrical induction. The feeding of raw material in the induction furnace is on intermittent basis. As one charge of scrap melts, slag is removed from the molten metal and certain alloys are added to achieve the desired grade of steel. Molten metal is then poured into refractory lined buckets from where it is further poured in different sizes moulds to get the desired size of steel cast . Ingot/Billet is allowed to cool down and then the product is separated from the moulds.

Flue gases are generated during melting of scrap. The characteristics and volume of these gases mainly depends upon type of scrap used in the furnace, i.e. with the degree of contamination in the Scrap. These flue gases need proper treatment for removal of dust particles/gases before being discharged into the atmosphere.

Steel scrap comes from various sources and generally has contaminants/coating etc on it. When this scrap is heated contamination/coating etc disintegrates from steel and comes out either as slag or becomes air borne, thus causing air pollution. The major source of Air Pollution is:

The volumetric capacity of Air Pollution cannot be judged as such, but fair engineering estimation can be made with input data like:

Selection of Technology for Equipment in an Air Pollution Control System in case of a Steel Re-rolling Mill depends upon the fuel to be used:

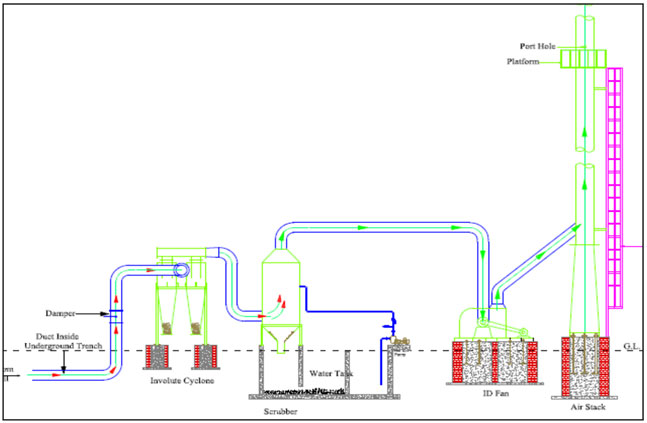

The Working of APCS for Steel Re-rolling Mill (Coal Fired)

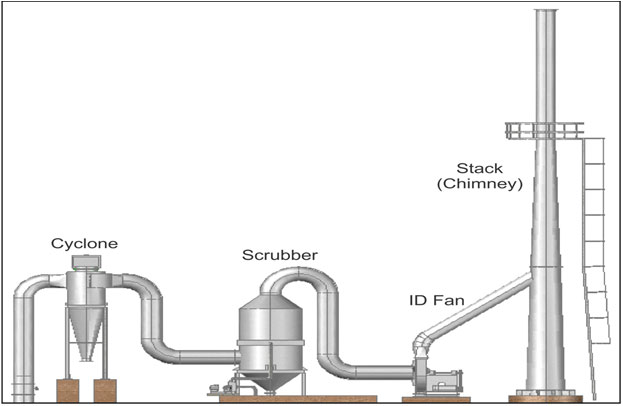

Air Pollution Control System for Steel Re-Rolling Mills (Coal Fired) is a Wet Type System. It consists of a high efficiency Cyclone followed by a Perforated Tray Type Wet Scrubber and a set of ID Fan and Stack.

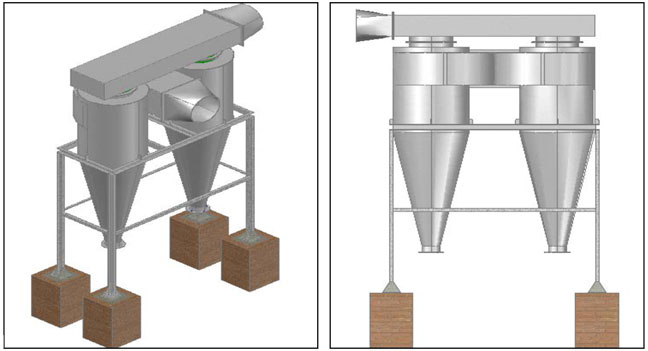

It is provided to capture the medium size particles from the furnace. The mechanism of the device is based on centrifugal forces entering in a tangential inlet cyclone. The medium size particles are arrested in the cyclone so that efficiency of scrubber with respect to fine particles increases.

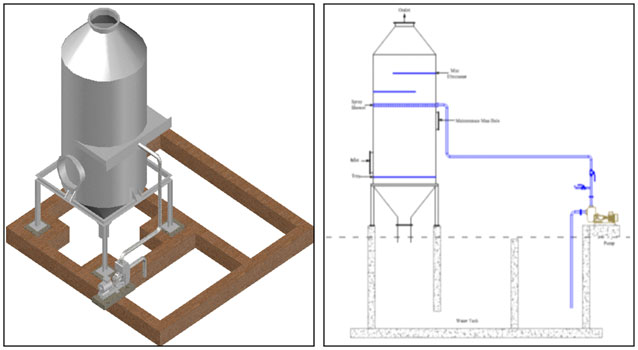

Unit has been provided with a Wet Scrubber. It is a perforated plate type single stage scrubber. Gases enter the scrubber from the side of the column and are showered with water spray as they move up through the tray and column, forcing them to shed the fine particles they are carrying. Further, they pass through a mist eliminator to ensure that no moisture is carried over from the scrubber. Water carrying dust particles is settled at the water tank below, which is partitioned in the manner to separate suspended particles while the water is recycled.

They have been provided for creating an adequate negative pressure in the system for efficient suction of gases.

Ducting and Bends are provided in the system for conveyance of gases at appropriate velocities and also to reduce the temperature by natural convection. An adequate length and size of ducting is necessary for proper conveyance of the gases at minimum pressure drop. The bends provided should be aerodynamic in shape so that there will be minimum pressure drop and no dust build up during operation. The main feature are

Under Updation

Under Updation

Under Updation

Under Updation

Under Updation

Under Updation

Under Updation