You are viewing: Home Waste Water Treatment

Water is a Prime Natural Resource, a basic human need and a precious asset. Water is so important to human existence, that it has been called “Elixir of Life” which literally means “Amrit”. This statement cannot be underestimated considering the fact that Human body is 75% water, the brain comprises 85% water, and blood is 92% water! However, equally paradoxical is the fact that of all the water available on our planet, only 1% is available for fresh water uses which support life!!

The use of water by mankind, plants, and animals is universal. Common sources of fresh water are rain water, surface water (in the form of rivers, lakes etc), ground water and water obtained from reclamation. Water maintains an ecological balance in the relationship between living things and environment in which they live.

The use of water is increasing rapidly with our growing population & Industrialization. With indiscriminate use and wastage, both the quantity of water available through various means has dwindled and its quality impaired. Hence it is imperative to conserve water as much as possible. Waste water should be treated and disposed off in systematic and scientific manner so as to maintain ecological balance and ensure sustainable development.

We at eros, are aware of this most important need and fully committed to provide performance oriented Waste Water Treatment Plants to help conserve water. Waste water can be generated from both domestic use (sewage) and industrial applications (trade effluent). It can have varied degrees of pollution depending upon the source of generation and hence customised treatment schemes both in terms of capacity and line of treatment are needed to be adopted.

In depth knowledge and experience enables us to suggest and implement only the best treatment solutions for our clients.

Sewage is the term used for waste water that is generated in the daily domestic chores related to sanitation, bathing, washing, cooking etc. it is basically water car-ried waste, but consists more than 99% of water.

This Sewage finds it way back into the environment and as its constituents are biode-gradable, they breakdown and are assimilated. However, with ever increasing popu-lation and usage of water, sewage is produced at a rate many times higher than the rate at which it can naturally be absorbed in the environment. Hence, its imperative vand also legally necessary that all sewage should be treated before its disposal so that it does not pollute the environment.

We at EROS, recognise this urgent need for action and have a range of solutions for comprehensively handling this problem and helping communities / industries pre-serve this precious resource.

Sewage Treatment is not only imperative for preserving our natural resources, it is also required so by the law. Following require treatment of sewage generated, before its discharge:

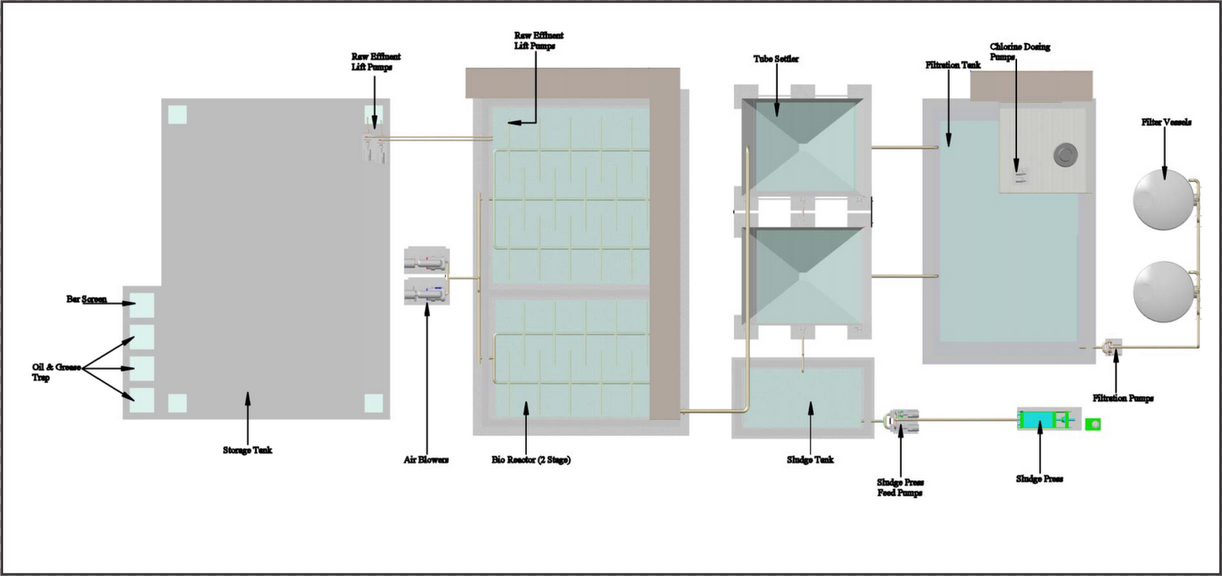

Process used at our Hybrid STP is a two stage biological treatment process. Developed and perfected in house, it is a combination of attached growth type Moving Bed Bio film Technology based stage 1 followed by suspended growth type Extended Aeration based stage2. This is followed by an advanced settler and a chlorine contact tank.

Also down the line is a set of filters to produce consistent results.

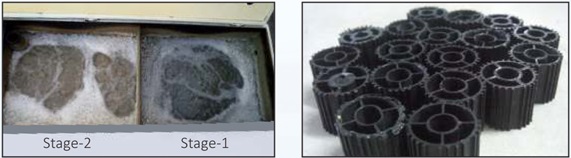

Use of precision designed PP Media ensures compact size and efficient treatment, and results even in low use periods.

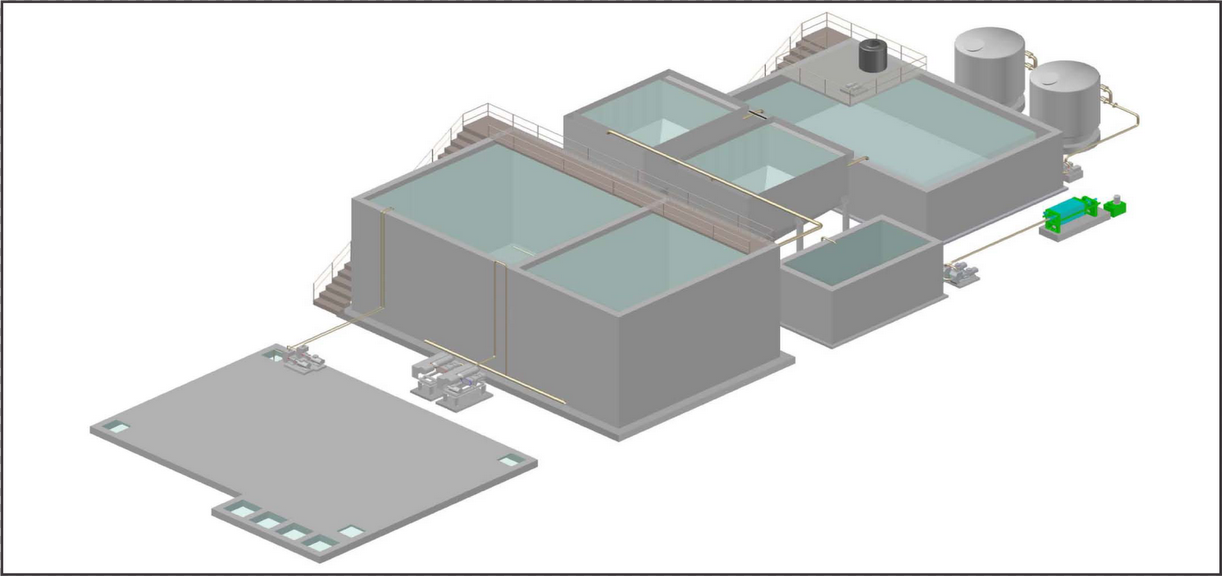

A MBBR based STP has a smaller footprint with clean layout for easy installation and operations.

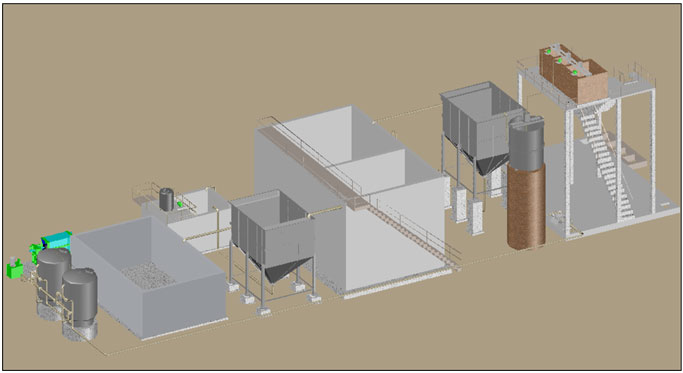

Isometric View of a Sewage Treatment Plant based on MBBR. Requires lower area per litre treated compared to other conventional technologies used. Adequate design and quality materials ensure guaranteed performance & results!!

Outlet Water Quality achieved by our Hybrid STP is very high due to the advanced technology at use.

| Parameters | Inlet (in mg/l, except pH) | Outlet (in mg/l, except PH) |

|---|---|---|

| Ph | 7.0-7.5 | 7.0-7.5 |

| TSS | 300 | < 25 |

| BOD | 300 | < 10 |

| COD | 600 | < 50 |

| OIL & GREASE | 25 | < 10 |

| TYPE | SEWAGE INDUSTRY |

|---|---|

| RESIDENTIAL COLONIES/APARTMENTS | 150 lts/ person/ day |

| INDUSTRIAL UNITS (DOMESTIC SEWAGE) | 50 lts/ employee/ day |

| HOTELS | 100-150 lts/ occupant & employee/ day |

| HOSPITALS | 100 lts/ bed/ day |

| EDUCATIONAL INSTITUTIONS | 50 lts/ student & staff/ day |

Sewage is the spent water stream generated after use of fresh water in various activities of domestic / non industrial nature, such as, washing water, food preparation wastes, laundry wastes, and other waste products of normal living, including sanitary waste water. This sewage, if discharged untreated into water bodies, leads to their pollution and degradation of the most valuable resource of all- water. Sewage hence needs to be treated before its discharge and after that, can also be reused for some applications, such as toilet flushing, ramp washing or gardening etc.

Sewage Treatment is not only imperative for preserving our natural resources, it is also required so by the law. Following require treatment of sewage generated, before its discharge:

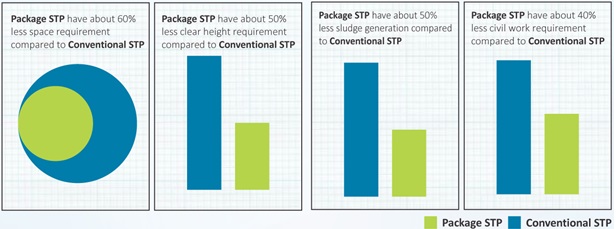

However, with rapid urbanization and scarcity or high cost of free space in our cities, a new problem of an effective STP with a low foot print and compact size has arisen. Also, in remote locations and communities where connection to a sewerage system is not available or viable, proper treatment of sewage poses a problem These issues can be effectively tackled with our lineup of Package STP for capacities from 5,000 lpd to 100,000 lpd, which provide odourless and clear treated water as small standalone units.

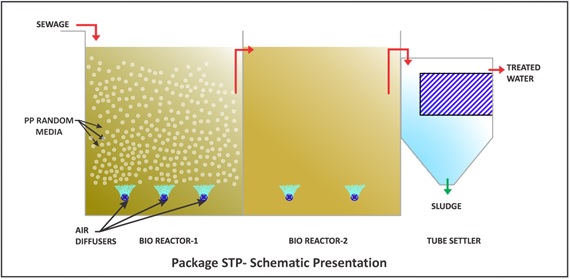

Process used at our Package STP is a two stage biological treatment process. Developed and perfect in house, it is a hybrid combination of attached growth type Moving Bed Bio film Technology based stage 1. Followed by suspended growth type Extended Aeration based stage 2. This is followed by an advanced settler and a chlorine contact tank. Also recommended is a polishing filter down the line to produce consistent results. Use of precision designed PP Media ensures compact size and efficient treatment, and results even in low use periods.

Aeration in Bio-reactor at Pac5 PP Media STANDARDS ACHIEVED BY OUR PACKAGE STP Outlet Water Quality achieved by our Package STP is very high due to the advanced hybrid technology at use.

| Parameters | Inlet (in mg/l, except pH) | Outlet (in mg/l, except pH) |

|---|---|---|

| pH | 7.0 - 7.5 | 7.0 – 7.5 |

| BOD | 300 | < 10 |

| COD | 600 | < 50 |

| TSS | 300 | < 25 |

| Oil & Grease | 25 | < 10 |

| MODEL | Capacity (KL/Day) | Dimensions w x L x H (m) | Area (m2) | Power (kW) |

| Pac5 | 5.0 | 1.75x2.0x2.0 | 3.5 | 3.0 |

| Pac10 | 10.0 | 1.75x2.7x2.0 | 5.0 | 3.0 |

| Pac15 | 15.0 | 2.0x3.4x2.0 | 7.0 | 3.0 |

| Pac20 | 20.0 | 2.0x4.2x2.0 | 8.4 | 3.0 |

| Pac25 | 25.0 | 2.0x4.5x2.5 | 9.0 | 3.25 |

| Pac30 | 30.0 | 2.0x4.8x2.5 | 9.6 | 3.75 |

| Pac40 | 40.0 | 2.0x6.2x2.5 | 12.4 | 4.25 |

| Pac50 | 50.0 | 2.3x6.5x2.5 | 15.0 | 4.75 |

| Pac60 | 60.0 | 2.3x5.0x2.5 | 11.5+ | 4.75 |

| Pac75 | 75.0 | 2.3x5.5x2.5 | 12.7+ | 5.5 |

| Pac100 | 100.0 | 2.3x7.25x2.5 | 16.7+ | 5.5 |

Under Updation

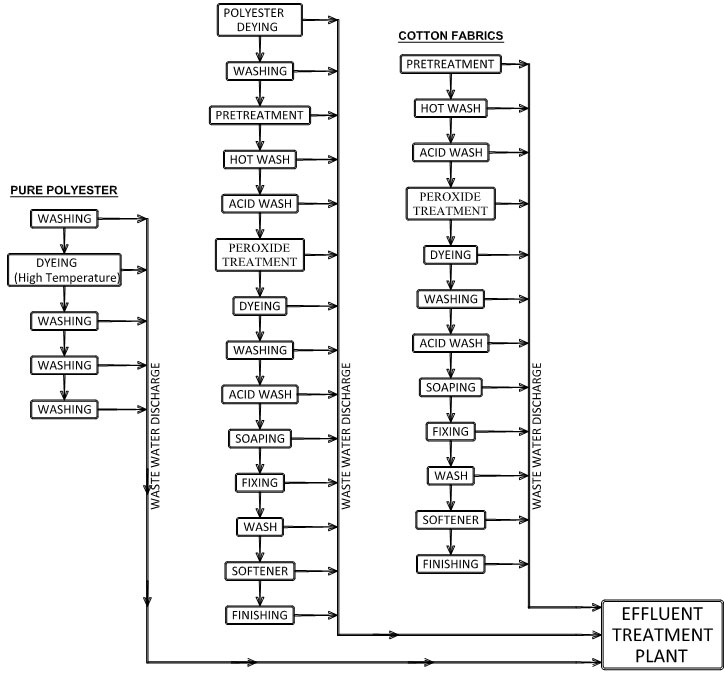

Textiles have one of the largest water footprints. Dyeing is a big problem both in terms of water use and pollution. It’s not realistic to stop dyeing and eliminate mass market products such as cotton and polyester. The Industry’s challenge therefore, is to adopt more water-friendly technologies and to effectively treat the water it uses.

While Industry is continuously trying to adopt modern processes to reduce water consumption, we at EROS, are helping them to treat the polluted water generated by them and therefore minimising the impact of water use.

Eros Envirotech (P) Ltd., is a Ludhiana (India) based environmental engineering company engaged in providing turnkey solutions for pollution control to industry in textile/ yarn dyeing and other fields for over a decade now.

We provide comprehensive and reliable solutions to the industry within cost and time parameters. Further, our design and project execution skills help us to engage client meaningfully to understand their requirements and deliver on that.

Polyester Cotton

Waste Water Treatment in Textile Dyeing is a multi stage process. They can be broadly classified as:

Further, another stage of Advanced Treatment can be added as per the laws governing the industry in the area or as per availability of fresh water or ease of disposal of treated water. This stage has not been covered in this introductory document.

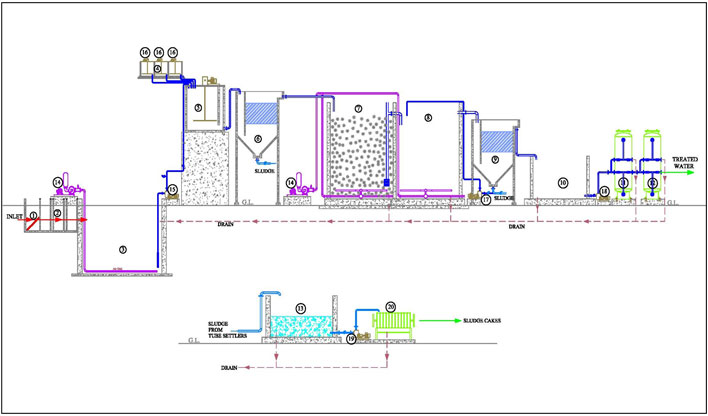

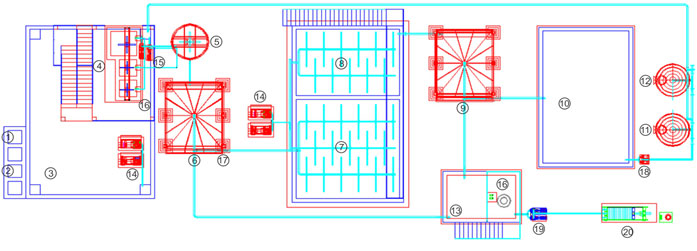

| 1. Bar Screen | 2. Oil & Grease Traps | 3. Bqualization Sump | 4. Dosing Tanks |

| 5. Flocculator | 6. Primary Tube Settler | 7. MBBR | 8. EA Reactor |

| 9. Secondary Tube Settler | 10. Prefiltration Tank | 11. Pressure Sand Filter Vessel | 12. Activated Carbon Filter Vessel |

| 13. Sludge Tank | 14. Air Blower | 15. Raw Effluent Lift Pump | 16. Dosing Pump |

| 17. Sludge Recirculation | 18. Filtration Pump | 19. Filter Press Feed Pump | 20. Filter Press |

| Type | Cotton Waste Water | Acrylic & Poleyser Waste Water |

|---|---|---|

| Parameters | Parameters | Concentration |

| Temperature | Ambient | Ambient |

| pH | 7.0-8.0 | 6.0-6.5 |

| TSS | 200-300 mgl | 200-300 mgl |

| TDS | 1500-1800 mgl | 800-1000 mgl |

| BOD | 300-400 mgl | 150-200 mgl |

| COD | 800-1000 mgl | 400-500 mgl |

| Temperature | Ambient |

|---|---|

| pH | 5.5-9.0 |

| TSS | <100 mgl |

| TDS | <2100 mgl |

| BOD | 30 mgl |

| COD | <250 mgl |

| Type | Consumption |

|---|---|

| Acrylic Yarn Dyeing | 80 L/KG |

| Poleyster Fabrics | 35 L/KG |

| Cotton Fabrics | 120 L/KG |

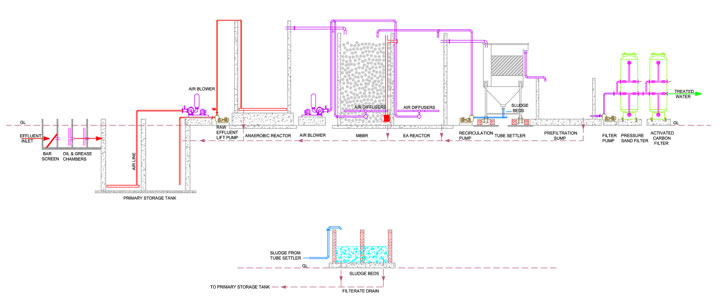

Primary Treatment involves physico-chemical treatment of influent to reduce TSS and colour from waste water. COD of water is also reduced to some extent in this stage.

Secondary Treatment involves biological treatment of water from first stage. This leads to reduction of BOD & COD to desired levels.

Tertiary Treatment is basically Filtration consisting of a Pressure Sand Filter & Activated Carbon Filter. They improve upon the parameters achieved in previous stages of treatment.

| 1. Bar Screen | 2. Oil & Grease Traps | 3. Bqualization Sump | 4. Dosing Tanks |

| 5. Flocculator | 6. Primary Tube Settler | 7. MBBR | 8. EA Reactor |

| 9. Secondary Tube Settler | 10. Prefiltration Tank | 11. Pressure Sand Filter Vessel | 12. Activated Carbon Filter Vessel |

| 13. Sludge Tank | 14. Air Blower | 15. Raw Effluent Lift Pump | 16. Dosing Pump |

| 17. Sludge Recirculation | 18. Filtration Pump | 19. Filter Press Feed Pump | 20. Filter Press |

Under Updation

Under Updation

Under Updation

Under Updation

Under Updation

For Milk Processing Industry, waste water emanates from spillage of milk and products thereof, and from cleaning of equipment that has been in contact with milk products. The concentration and composition of the waste depends on the production programme, operating methods and the design of the processing plant. Being organic in nature, the pollution load from the processes is quite high.

While Industry is continuously trying to adopt modern processes to reduce water consumption, we at EROS, are helping them to treat the polluted water generated by them and therefore minimising the impact of water use.

Eros Envirotech (P) Ltd., is a Ludhiana (India) based environmental engineering company engaged in providing turnkey solutions for pollution control to industry in textile/ yarn dyeing and other fields for over a decade now.

We provide comprehensive and reliable solutions to the industry within cost and time parameters. Further, our design and project execution skills help us to engage client meaningfully to understand their requirements and deliver on that.

For Milk Processing Industry, waste water emanates from the following sources:

These type of effluent are generated in all types of Milk Processing Units including:

It is pertinent to mention here that neither the processes, nor the type of product being made as listed above is an exhaustive list. They are indicative of the gamut of operations in which the industry is involved.

Typical characteristics of untreated waste water are as below:

| Parameters | Concentration |

|---|---|

| Temperature | Ambient |

| pH | 7.5 – 8.0 |

| Oil & Grease* | 200 mgl |

| BOD | 1200 mgl |

| COD | 2500 mgl |

| TSS | 400 mgl |

| TDS | 800 mgl |

*Certain operations like Cheese Making will have higher Fat content (Whey) in their discharge. It may need additional treatment and has not been discussed in this document.

Treated Effluent will have characteristics as below:

| Parameters | Concentration |

|---|---|

| Temperature | Ambient |

| pH | 7.0 – 8.0 |

| Oil & Grease* | 10 mgl |

| BOD | 30 mgl |

| COD | 100 mgl |

| TSS | 100 mgl |

| TDS | 800 mgl |

Waste Water passes through a Bar Screen & Oil & Grease Trap is stored in a two partitioned Equalisation cum Storage Sump. An Air Blower with an Aeration Grid is provided here to continuous agitation and mixing. From here it is lifted with the help of a Raw Effluent Lift Pump to an Anaerobic Reactor. This is a suspended growth type Bio-reactor where bio-mass develops and metabolises organic impurities in the absence of air. Required water re-circulation rates are maintained in the reactor through the feeding pump it self.

Waste Water is then fed to a State of the Art MBBR (Moving Bed Biological Reactor). Here Bacteria Culture develops on Random Floating Media. These micro-organisms derive their food from the organic impurities in water and air from an Air Blower which diffuses air in Fine Bubble Form at the bottom of the reactor through Membrane Diffusers. This is followed by a polishing EA Reactor (Extended Aeration) where air is provided with the help of Air Blower and diffused through Diffusers to improve upon the results of the MBBR. This reduces the BOD Load of the Discharge significantly.

Water from here is fed to a Highly Efficient Tube Settler where finer suspended impurities as well as dead organic matter from the MBBR is settled and dumped to Sludge Drying Beds. Part of Sludge is recycled in the system using a Sludge Recycling Pump.

Water after Tube Settler is stored in Pre-filtration Sump and is pumped through a Filtration Pump to a Pressure Sand Filter and an Activated Carbon Filter. It removes very fine suspended particles in the Discharge Stream, as well as traces of any impurity or any odour or colour inherent in the stream. BOD and COD of water is further reduced during Filtration.

Treated Water is then fit for disposal into Municipal Sewers or for use in Irrigation & Plantation on Land.

Under Updation

Under Updation

Under Updation